ABOUT US

Why Our Moisture-Cured Urethane Coatings Are the Right Choice for Your Next Project

MCU-Coatings® supplies advanced moisture-cured urethane systems across Australia and New Zealand. Our single-component, fast-drying, surface-tolerant coatings react with atmospheric moisture to form durable polyurea linkages that bond strongly to steel, concrete and mixed substrates.

Independent ISO 12944-6 testing has verified +25 years to first maintenance in a C5 environment using only an ST3 surface preparation, demonstrating the strength of our chemistry and the robustness of our two-coat, thin-film system.

With more than 5,000 bridges and major infrastructure assets protected globally, MCU-Coatings® has been proven on millions of square metres across marine, hydro, wastewater, offshore, petrochemical, transport and defence applications.

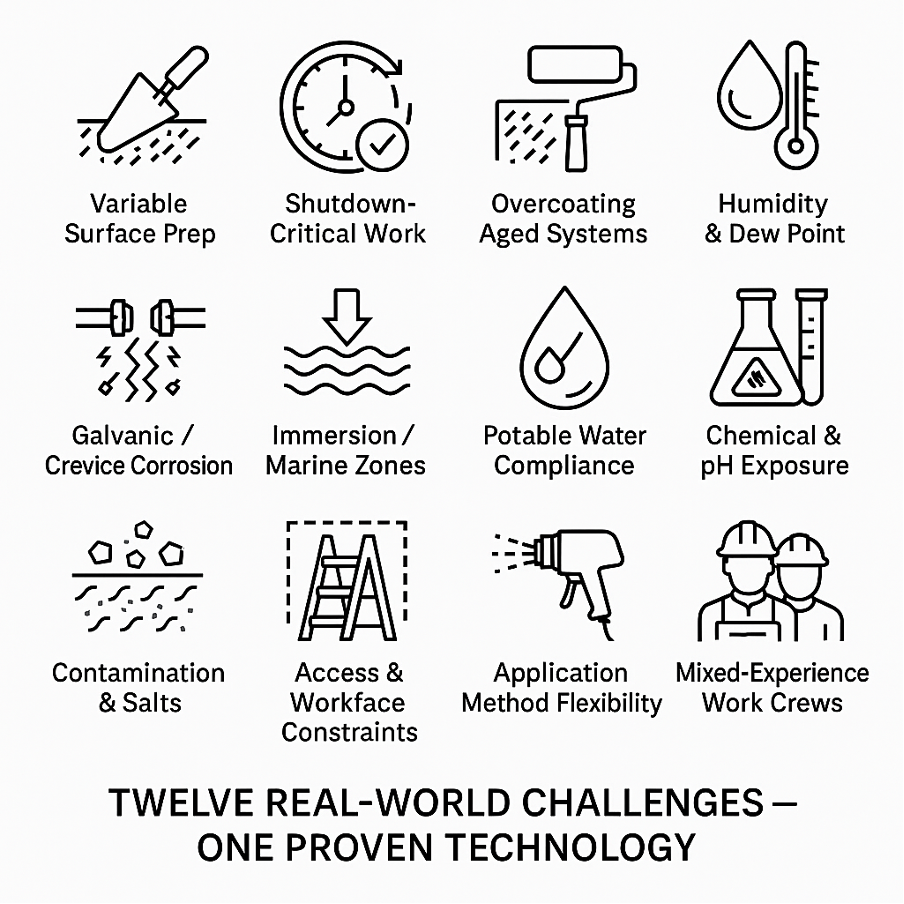

The twelve solution areas below reflect the most common maintenance, application and operational challenges faced by asset owners, engineers and contractors.

Each section explains how MCU-Coatings® helps you:

- reduce risk,

- improve productivity, and

- achieve predictable, long-term performance under real-world site conditions.

Solving Real-World Challenges

MCU-Coatings® reduces application risk, simplifies specifications and delivers long-term protection for utilities, water assets and bridges.

Find out more

Asset owners, engineers and applicators face technical, environmental and operational challenges every day. Often with significant cost, safety and schedule implications. MCU-Coatings® helps solve these challenges by reducing application risk, simplifying specifications and delivering durable, long-term protection.

Our coating systems are designed to:

- solve complex corrosion and maintenance problems

- deliver long-term asset preservation outcomes

- significantly improve application efficiency · support on-time, on-budget project completion

Because many engineers and applicators are unfamiliar with how moisture-cured systems differ from traditional technologies, we provide application guidance and system familiarisation to help teams adjust smoothly. For remote or fast-mobilisation sites, we also provide mobile app–based support during project start-up.

Working With Asset Owners

We align our solutions with your maintenance strategy, whether work is self-performed or delivered by contractors.

Find out more

Utilities, water authorities and bridge asset owners face unique maintenance realities, constrained shutdowns, workface limitations, environmental controls and ageing infrastructure. MCU-Coatings® works with your maintenance strategy, whether you self-perform coating work or engage specialist contractors.

We tailor our specifications based on the constraints of your site, including:

- Access limitations

- Hot-work restrictions (e.g., tank farms)

- Water or power availability

- Equipment limitations

- Contamination and ageing surfaces

- Varying crew skill levels

- Short or infrequent shutdown windows

Our goal is to help you maximise the return on every maintenance dollar by designing coating systems that perform under real operating conditions. Not every project can achieve ideal surface preparation. We design solutions that balance best-practice intent with what is genuinely achievable — especially when the goal is to stabilise corrosion, extend life between recoats or manage operational risk. At the same time, we support and encourage best-practice preparation wherever access, shutdown conditions and budgets allow.

Our specifications, application guidance and system familiarisation ensure that whether your maintenance is carried out internally or by contractors, teams understand how MCU-Coatings® behaves differently — and how to get predictable, high-quality results. We offer a simpler system.

Our Unique Solutions

A compact, high-performance suite designed to solve problems that traditional coatings struggle with.

Find out more

MCU-Coatings® technologies protect ferrous and non-ferrous metals and concrete across diverse industries and climates. Designing the right solution requires deep understanding of site conditions, asset behaviour and operational constraints.

Ask us about:

- Our 2-coat, thin-film system

- Applying MCU-Zinc or MCU-Miozinc at 210 μm WFT (150 μm DFT) in a single coat

- Our 3-in-1 zinc primer process (crevice seal + stripe coat + prime in one step)

- Our nuts-and-bolts galvanic crevice-sealing technique

- Using MCU-Ecocleaner to wet-out or clean inaccessible areas (plate gaps, bolted joints, riveted overlaps)

- Our AS/NZS 4020 potable water system (APAS pending local production)

- MCU-Flex for sealing voids and preventing moisture ingress in steel or concrete

Low or Variable Surface Preparation

Strong adhesion on ST2, ST3, UHP, WAB, mechanical prep — ideal where blasting is restricted.

Find out more

Many assets cannot be fully blasted due to operational limits, access issues, contamination or environmental restrictions.

MCU-Coatings® adheres strongly to surfaces prepared to:

- ST2 / ST3

- UHP water jetting

- Wet abrasive blasting (WAB)

- Mechanical cleaning

- Sa 2 where suitable

This enables practical, economical maintenance without sacrificing long-term performance.

Shutdown-Critical / Fast Turnaround Work

Ideal for utilities, ports and industrial assets where return-to-service is critical.

Find out more

Many assets cannot be fully blasted due to operational limits, access issues, contamination or environmental restrictions.

MCU-Coatings® adheres strongly to surfaces prepared to:

- ST2 / ST3

- UHP water jetting

- Wet abrasive blasting (WAB)

- Mechanical cleaning

- Sa 2 where suitable

This enables practical, economical maintenance without sacrificing long-term performance.

Overcoating Aged or Unknown Systems

Strong bonding to aged coatings, galvanised steel, aluminium and weathered steel.

Find out more

MCU-Coatings® supports practical maintenance strategies such as:

- spot repair + overcoat

- full overcoating of aged systems

- encapsulation of lead-based or asbestos-containing coatings (under controlled procedures)

Our systems bond well to galvanised surfaces, aged paint, aluminium and weathered steel.

High-Humidity & Dew-Point Challenges

Applies and cures through moisture, where traditional coatings must stop.

Find out more

MCU-Coatings® applies and cures reliably in:

- 6–99% humidity

- surfaces near dew point

- –20°C to 50°C ambient temperature

Galvanic & Crevice Corrosion

Tailored solutions for nuts and bolts, overlaps, angles and complex steelwork.

Find out more

We provide engineered approaches to extend life in complex interfaces:

- zinc-rich crevice sealing

- stripe-coating systems

- 3-in-1 galvanic zinc primer technique

- MCU-Flex void filling to block moisture pathways

This enables continuous work during weather shifts or in moisture-prone environments such as pump stations, galleries, marine structures and utility assets.

Immersion, Tidal & Splash Zones

Reliable long-term performance in harsh marine environments.

Find out more

MCU-Coatings® performs in:

- full immersion

- inter-tidal zones

- splash zones

- areas with mechanical and salt loading

Ideal for ports, wharves, dolphins, piles, fenders and coastal structures.

Potable Water & Sensitive Environments

AS/NZS 4020-compliant system for drinking-water contact.

Find out more

Our potable water system is compliant with AS/NZS 4020 and suitable for:

- reservoirs

- potable tanks

- clarifiers

- galleries

- water infrastructure

(Additional APAS certification pending local production).

Chemical, pH & Contamination Constraints

Specifications tailored to chemical exposure, contamination and substrate condition.

Find out more

We factor in:

- pH

- presence of salts or zinc corrosion products

- chemical exposure

- substrate age/condition

- environmental contamination

This ensures predictable long-term performance.

Application Constraints & Methods

We help experienced applicators adapt quickly to MCU-Coatings® systems.

Find out more

Through application guidance and system familiarisation, we support crews applying MCU-Coatings® by:

- spray

- brush

- roller

This ensures consistent, reliable performance, regardless of crew experience or site limitations.

Partnering With MCU-Coatings®

Custom solutions that reflect your site realities, constraints and goals.

We welcome the opportunity to present customised solutions and compare them with standard industry specifications.

Our aim is simple: solve problems, reduce risk and deliver predictable results, every time.

Protect more. Waste less. Finish faster.

Talk to our team today about specifying MCU-Coatings® for your next project.

MENU

HOME

ABOUT

SECTORS

PRODUCTS

APPLICATORS

SUSTAINABILITY

ARTICLES

CONTACT

Contact Info

Australia & New Zealand